Downloads

Getting Started with Asset Operations Management

If you’re sold on the idea of implementing an Asset Operations Management (AOM) program and reaping the many benefits to your maintenance, reliability, and operations functions, as well as to the overall performance of your company, it’s time to get started.

Unlock Your All Access Pass

Establish Clear Objectives

The first step is simple: establish clear objectives for your Asset Operations Management (AOM) program. Like any successful initiative, you’ll want to understand where you want to go in order to figure out how to get there. With something as powerful as AOM, it can be easy to get wrapped up in the potential improvements across so many areas that it can be challenging to focus on your biggest pain points. However, that’s exactly what you need to do to optimize AOM performance, see substantial and rapid return on investment, and obtain management and employee buy-in to continue investing in the system in the future.

Common Objectives to Consider

Some organizations may be able to immediately identify their most significant maintenance or asset problem while others may have a more difficult time selecting top priorities. To help you discern where to focus your efforts, here are some common possibilities:

Reduce equipment breakdowns. If mission-critical assets are routinely breaking down, causing unplanned downtime, and leaving your workers with nothing to do, that’s a clear indication that finding a way to reduce those breakdowns should be the primary objective of AOM.

Ease administrative burden. Some businesses find their documentation system is cumbersome and time-consuming, requiring as much or more time to record preventive maintenance tasks than to actually perform them. AOM can help reduce this administrative burden, freeing up more maintenance time for repairs and proactive work.

Support predictive maintenance processes. If you have reactive and preventive maintenance under control, the next level of performance comes from predictive maintenance. AOM can help better support and manage sensors and alerts as well as analyze the data that comes from such tools.

Improve MRO inventory management. The inability to effectively manage MRO inventory can be a huge waste of time and labor. If you find that your team is unable to locate the tools, equipment, and supplies necessary to maintain productivity, this may be an excellent objective for your AOM system.

Track maintenance data. The amount of data is overwhelming today. The key to better decision making is to not only be able to gather all data in a centralized and comprehensive way, but to be able track it over time and then extract insights that can help a company take effective action.

Regardless of whether you select one or more of these or other objectives, you’ll want to be sure you establish clear goals that are based on your specific business’ needs.

Tips on Selecting Objectives

Although the executive spearheading the AOM initiative may have some ideas of which objectives would be most appropriate, remember that the AOM model is based on a transformation of culture that must permeate all levels of the organization.

As such, it’s critical that you incorporate all levels and personnel in this initial step of setting clear objectives. Take time to discuss the question with technicians, supervisors, and managers. Find out what is making it difficult for them to succeed in their individual jobs and on their specific teams. Chances are the same type of issues will surface for many.

Once you select and articulate objectives, be sure to tie the AOM effort back to the input you received during the inquiry phase, so all employees feel part of the bigger effort. If technicians, supervisors, and managers feel heard and believe their own issues are being addressed through the AOM initiative, they will be much more likely to actively participate in the new program.

After your organization has made the final decision about initial goals, you can determine which tools or modules you may want to purchase, as well as identify workflows and processes that may need to be established or changed.

It’s also important to periodically check in with your employees to gather feedback on how they perceive objectives are being met. This information will not only help you share progress and small successes along the way, but also give you data to help you adjust and tweak the AOM system as you move forward to have an even greater impact. Establishing clear objectives will help you determine and measure the extent of your AOM implementation success.

Achieve Buy-In at All Levels

The successful implementation of (AOM) usually requires a radical shift in culture and employee mindset. The change management aspects of AOM are just as important as the tools and technologies required for implementation.

We’ve discussed the importance of setting clear objectives before beginning any AOM tactical implementation. Now, we’ll continue on our journey, focused instead on the importance of achieving buy-in at all levels of the organization.

What’s in It for Me?

It’s human nature to want to understand how something new will impact the self. This is clearly the case within businesses where existing individual job demands often consume a great deal of time and energy already.

One key to achieving comprehensive buy-in is to clearly communicate the benefits and impact of AOM to each individual team, department, and individual. Employees must understand not only why AOM is good for the organization as a whole, but also how it will help them individually in their jobs and careers. Without this understanding, there can be little motivation to participate in a productive way.

Begin at the Top

The beauty of AOM is that it clearly connects KPIs from the maintenance and manufacturing floor to high-level business objectives. It’s no longer only about measuring activity and task completion but shifts the focus to the value created by each and every individual.

The senior management team will need to approve the resources required for AOM, so beginning at the top is important. If corporate-level objectives were clearly defined to reflect executive pain points like downtime or production level concerns, it should be simple to show how AOM will visibly improve those top-line metrics.

Middle Management Believers

Line/production managers and shift supervisors are often stuck in the middle, trying to meet the demands of top management as well as motivate and direct technicians and employees. They traditionally have had responsibility for more specific key performance indicators related to production quotas, equipment downtime, or schedule adherence.

AOM is well-positioned to make their jobs significantly easier, empowering them with the tools and technologies to help their teams be more productive and access the information they need when they need it. Centralized data means middle management has a single source of truth on which to base day-to-day decisions.

Reaching All Employees

Ultimately, every employee has an important role to play within an AOM system. Even entry-level staff can gain important insights to their jobs as well as have a responsibility to add to the repository of knowledge.

For example, a new maintenance technician assigned to a simple repair can immediately see all the historic data related to a specific piece of equipment, in addition to checklists, pictures, and instructions. An AOM system can connect that technician by phone or messaging to experts within the company if a consult is required, making the task at hand easier. On the other hand, that technician must completely and accurately record the repair being performed within the AOM system, so that data becomes part of the centralized repository for future use and analysis by others in the organization.

Maximizing Results

In the end, achieving buy-in from all levels of your organization before and during AOM implementation means your company is better able to achieve best practices and optimize asset performance.

Individual technicians are no longer focused on disconnected tasks that just lead to a paycheck, but instead, believe they are valuable team members adding to the performance of critical equipment. Managers and supervisors shift their focus from simply tracking activity to looking at the value their teams add to the overall operation of the company, then that information rolls up to the executive team, speaking to metrics around revenue, cash conservation, and profit margins.

In the end, better performance means higher levels of customer satisfaction, which leads to loyalty, growth, and success.

Create an Implementation Team

Once you’ve established objectives and obtained buy-in from all levels of your organization, it’s time to focus on the people. Creating a solid implementation team is crucial when planning an AOM implementation. This team is one that will bring your company through the difficult moments that are inevitable during the transition process, and the people you choose for each role within the team will have a significant impact on the system’s success. Be sure to dedicate time and effort to determining where team members can perform at their best.

Select an Asset Operations Manager

A stellar team starts with a strong leader. The first step to building a great team is selecting an asset operations manager, who essentially carries out the AOM vision—the optimization of critical assets within a company.

While experience in maintenance, reliability, and operations may be an advantage for a candidate, at the end of the day, leadership skills are most important.

An asset operations manager must:

Lead and manage AOM implementation: As per the title, the asset operations manager is responsible for managing the entire AOM implementation from start to finish—and onward.

Consolidate resources: Part of managing an implementation process is keeping track of resources. An asset operations manager tracks, manages, and consolidates resources to keep the implementation moving forward.

Define key performance indicators (KPIs) for the team: Every company, every team, and every implementation process is a little different, and the same goes for AOM and your organization. As a result, track KPIs that correspond with your particular situation. An asset operations manager takes care of the forethought that goes into determining which KPIs will be most beneficial.

Manage team member responsibilities and performance: An implementation team must work as a group to experience success. The goal of the manager is to appoint team members to tasks that suit them, constantly supervising performance and shuffling roles around as necessary. It’s also essential to realize that a certain amount of communication with team members is important to understanding individual needs; be sure to create regular opportunities for feedback, both for the manager and the team.

Report results to stakeholders: Very early on in the implementation process, stakeholders are going to want to see results, whether positive or negative. The asset operations manager is responsible for understanding, tracking, and communicating results throughout the implementation process and beyond.

Select and oversee the implementation of related technologies: AOM isn’t a one-time software implementation; it involves other technologies that are essential to performance. The asset operations manager must determine the best tools, technologies, and software for the company’s needs and oversee their purchase and implementation.

Define the Asset Operations Team

A leader can’t do much without a team, and the people you choose to fill roles within a team are every bit as important as the manager.

Selecting team members may be difficult as many factors likely play into the decision. Understanding what will be expected from your team may help you determine the employees who will fulfill the various roles most effectively. Members should:

Understand the vision of AOM: AOM is designed to optimize every critical piece of equipment. Ensure team members know, understand, and are committed to this vision for your company.

Work together to create goals: Goals are absolutely necessary; they give a company a direction to work toward. With the asset operations manager, the team members should work together to form goals that are specific, measurable, achievable, relevant, and time-bound. Team members should understand that both individual performance and overall progress will be judged based on the achievement of those goals.

Define KPIs together with the asset operations manager: KPIs are a great way to track and measure outcomes. As mentioned above, discovering the KPIs that are most beneficial to your organization takes some reflection and thought. Both team members and the manager should be involved in this discernment.

Track and communicate progress using KPIs: The team should regularly and consistently watch its progress within the KPIs. This progress should be tracked and communicated to the manager.

Meet with the AOM manager: Communication is key within any team, and so team members should regularly meet with the manager to discuss specific roles and responsibilities, schedule and assign tasks, and receive feedback and support.

Implementation Best Practices

Once you’ve decided to implement AOM, it’s time to start looking for some guidance. Below are some best practices that will help you through the steps you need to ensure the smoothest, most successful implementation possible.

Since AOM consolidates existing technologies, initiatives, and processes, implementation may simply involve reorganizing the systems you’ve already installed. While this may streamline the process, it also makes it easy for team members to slide back into old habits. Implementation is never easy, but giving certain areas the attention they require can certainly speed the process. As you begin the process of implementing AOM, keep the following components in mind.

Ongoing Training

Technology struggles are often a barrier during any implementation process as staff members usually find software systems difficult to use. This results in solutions being used incorrectly, which in turn decreases effectiveness and frustrates team members. Staff may retaliate by turning back to old systems and refusing to work as a team to understand and implement AOM.

Your team is an integral aspect of the implementation process, and it’s important to give them the resources they deserve. AOM is a user-friendly solution, but it’s not immune to technology difficulties; it minimizes but doesn’t eliminate the need for training. New or struggling employees should have plenty of opportunities to learn more about the system, even after implementation is well underway. Additionally, staff should have the freedom to ask questions and learn more about the system on an ongoing basis.

It’s understandable that, with all the expenses of implementation, businesses need to look for ways to save. However, skimping on training only compromises AOM’s success.

Infrastructure Upgrades

Before AOM can be implemented, your IT network might need an upgrade. AOM cannot flourish without the IT infrastructure to support it. For example, AOM requires a reliable internet connection in order to operate dependably. Additionally, an intranet should be stable as well for top performance.

Poor IT infrastructure has far-reaching disadvantages. If the system functions slowly, team members may lose faith in AOM before giving it a fair chance and may even use it as an excuse to revert back to old systems. Like poor training, inadequate technology puts AOM’s success in jeopardy. It makes no sense to spend resources on AOM only to have it fail, so invest in your infrastructure technology—it’s worth it.

Change Management

As mentioned above, the first step for successful change management is to remove obstacles such as limited training and inadequate technology. However, though sufficient training and infrastructure will definitely help your team make great strides within the implementation process, it may not change staff behavior overnight. People tend to resist change, even for the better, once they’ve settled into a routine. As a result, it’s important to formulate a plan to overcome the challenges of change before they happen.

An integral part of change management is transparency. Operations, maintenance, and reliability teams need to know how new processes will work and what will be expected of them.

All teams will react to AOM differently and no one knows your team better than you. It’s important to tailor your management plan to your particular situation by communicating with team leaders and predicting difficulties.

Planning

AOM has potential for any company, but it won’t miraculously reach that potential as soon as implementation is completed. Oftentimes careful planning is overlooked or forgotten in the chaos of implementation. A successful AOM implementation requires an action plan that includes data tracking, functionality, budget, and stakeholder approvals.

Here are some of the questions you should ask when designing an implementation plan.

Are team members and leaders able to communicate on the same page?

Do we have an operational blueprint designed and scheduled?

Has the software been tested?

How will data be migrated and centralized from previous systems?

Data Quality

Managing data quality is an overlooked but important area. You’ll get out of AOM just what you put into it. As a result, maintenance, reliability, and operations teams need to learn how to input quality data so that you’ll get more accurate data out. For some companies, hands-on training sessions are a great way to manage data quality. For others, you may need ongoing incentives and communication about the importance of data quality and how it affects the performance of every team and individual.

Want to keep reading?

Maintenance

Guide to Maintenance & Reliability Work Management

Maintenance

Cultivating Maintenance Excellence: The Role of Culture and Leadership in Reliability

Maintenance

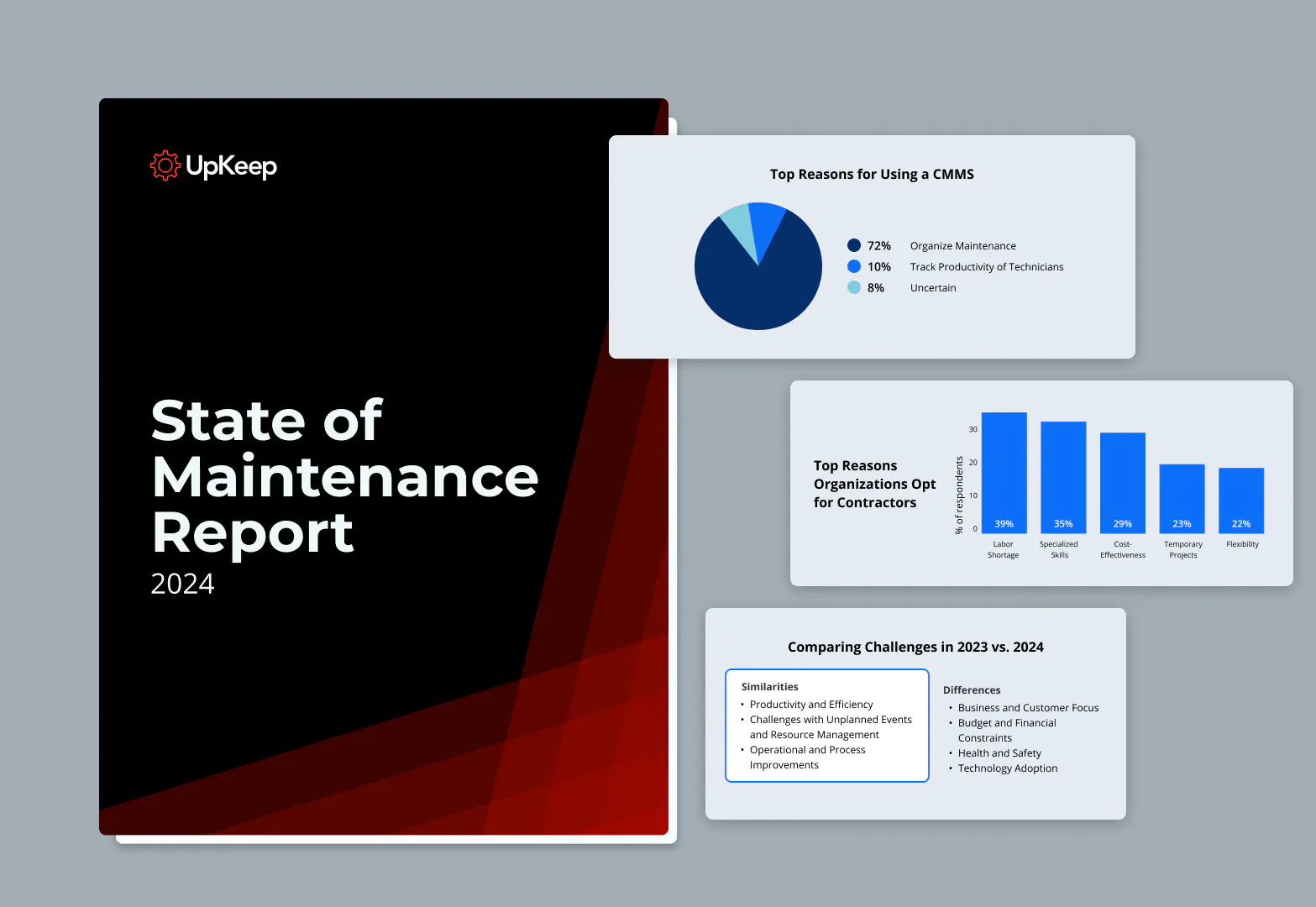

State of Maintenance Report 2024

4,000+ Companies Rely on UpKeep's Asset Operations Management Software